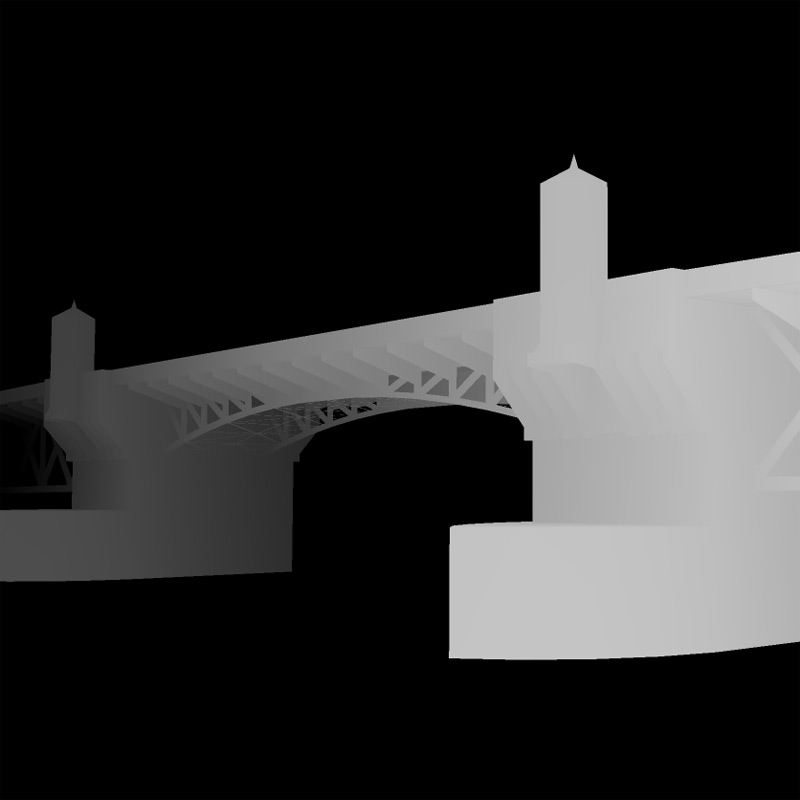

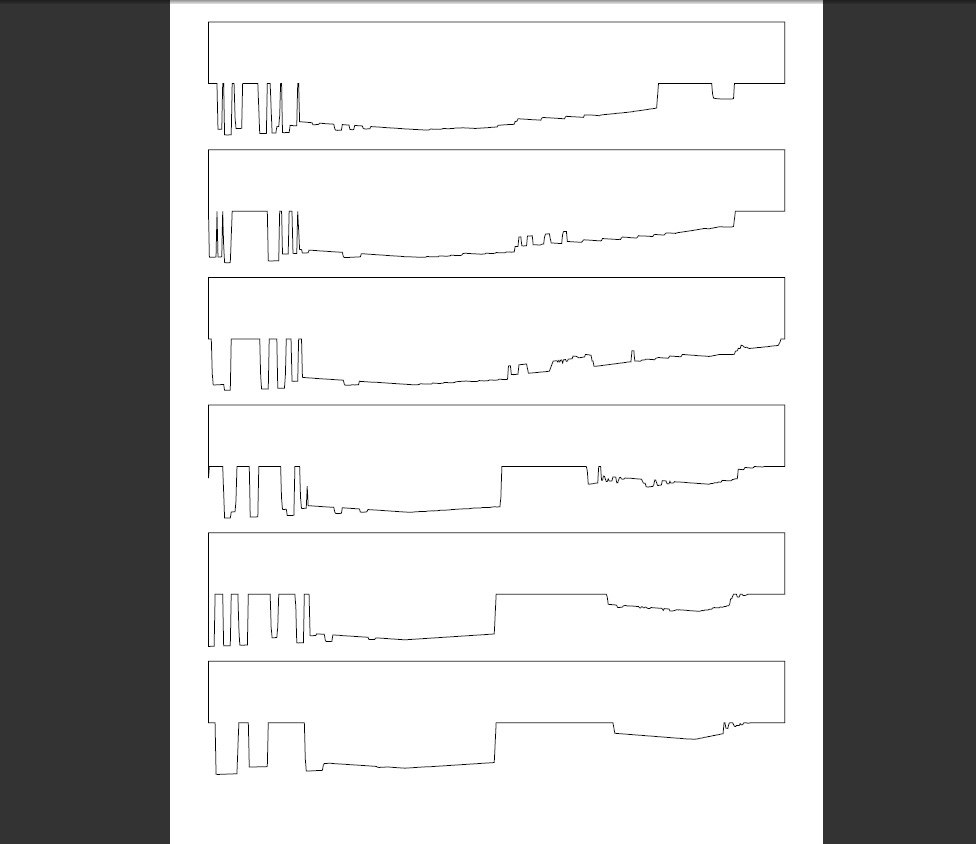

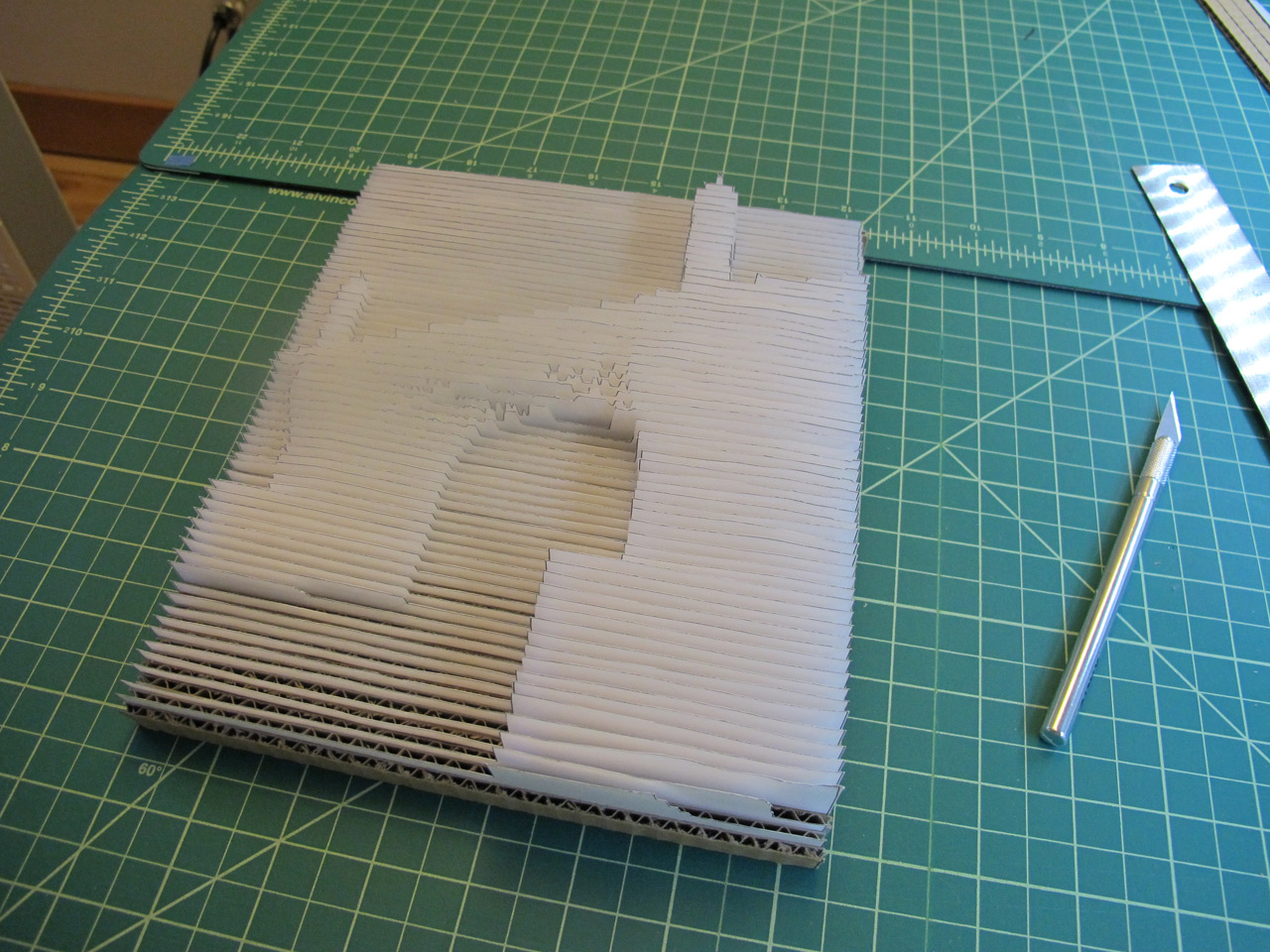

I've been playing with this idea for a while and finally spent a few grueling hours with an exact-o knife in order to knock out a little proof of concept before I spend the time and money having a bunch of material cut out via CNC or something. This process involves sampling "slices" of a depth map at fixed intervals and using each slice to create a vector profile. The resulting output is a set of long vector shapes that collectively approximate the original model and can be rendered in any size and from any material (well, any flat material).

This set of images shows the initial depth map, an example of the vector output from my processing sketch, and a paper prototype.

The first few paper prototypes look good and I'm confident this process will scale up very well. Imagine a 20 foot wide 3d wall-scape made from stained birch plywood strips, connected vertically by steel rod. If you're looking for some stunning artwork for your home or business then look no further!

This whole idea started with a topological map of mount St. Helens I found online. Soon after that I started looking for methods of generating depth maps so I could use any arbitrary 3d geometry. As luck would have it, rather than having to familiarize myself Blender I found a tutorial video for faking depth of field in SketchUp which works great as a way of creating depth maps.